| |

| |

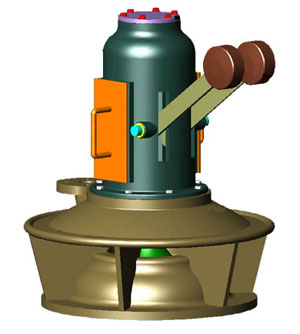

ANTI-VACUUM VALVES |

| |

|

| |

|

| |

|

| |

|

| |

Accumulated air can cause catastrophes to the pipeline systems. Generation of vacuum leads to pipeline implosion or pressure transients. The preventive course is use of efficient Air Release valves & use of Anti-Vacuum Valves at the critical locations of the pipeline that are prone to vacuum generation. The R & D Multiple’s Anti- Vacuum valves are designed & manufactured to be extremely responsive & sensitive to the pressure decrease in the line. They instantly allow the entry of sufficient quantity of air at the slight hint of the inception of vacuum & preclude the possibility of vacuum build–up. |

| |

|

| |

SALIENT FEATURES : |

| |

|

| |

- Size range: 150 to 400mm. Pressure ratings: PN10 / PN16 & PN24.

- Material Options: C.I., S.G.I., C.S. (WCB) for Body & Cover, Bronze Dashpot & Seat Ring & Guide Bushes & SS Shaft, Pins, Links & levers.

- Hydraulic Dashpot arrangement to eliminate slam in closing of the AVV.

- Externally adjustable Counter-weight arrangement to set the closing torque.

- Large cowl type covered valve body eliminating any possibility of internal assembly being tampered-with.

- Provision for mounting of an isolating sluice valve & Air Release valve on the body of the AVV is given.

|

| |

|

| |

SPECIAL FEATURES : |

| |

|

| |

- Large aero-dynamic flow passages ensuring quick entry of large volumes of air.

- Resilient seat fixed into the Valve Body giving drop-tight shut-off during normal operation.

- Critically balanced dashpot, cwt & disc assemblies ensuring that with slightest hint of vacuum formation in the pipeline, the disc opens to allow entry of large volume of air.

- Sturdy, robust cast construction of the valve body & disc. Body provided with swirl busting ribs.

- Non-Ferrous liner bush bearings provided for shaft & pins at all rubbing joints. This minimizes friction, enhances the availability of the valve & increases its service life.

|

| |

|

| |

|

| |

|

| |

|

|

|